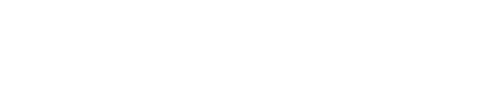

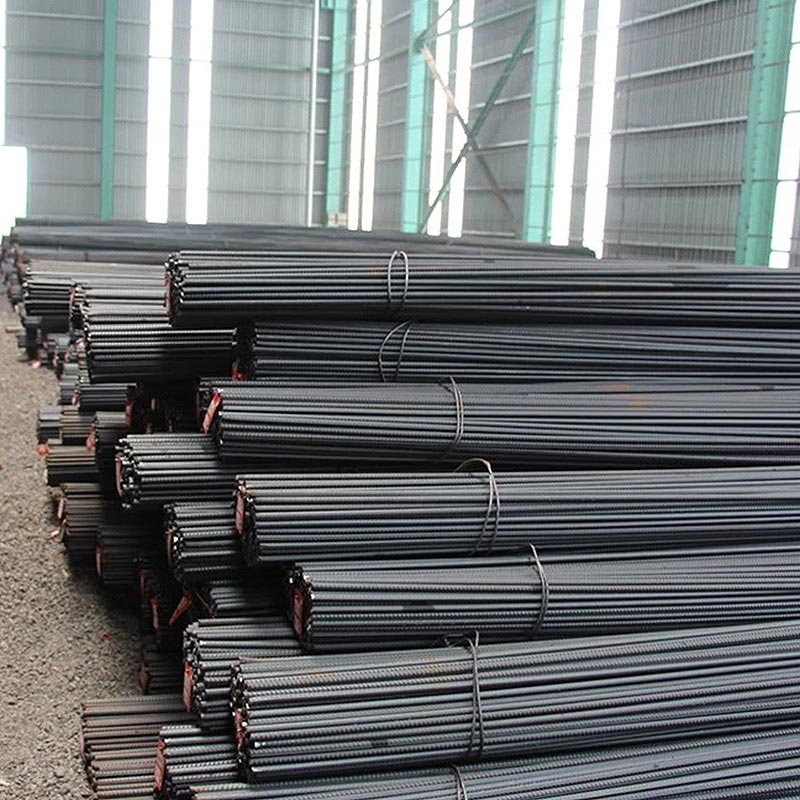

Steel Rebar

● Steel rebar, short for reinforcing bar, is a steel rod used to strengthen concrete structures. Made primarily from carbon steel, it features ridges or deformations on its surface to bond tightly with concrete.

● Classified by strength and composition, common grades include ASTM A615 (carbon steel) and A706 (low-alloy). It enhances concrete’s tensile strength—critical since concrete is strong in compression but weak in tension.

● Widely used in construction for buildings, bridges, roads, and foundations, rebar comes in various diameters and lengths. It’s often tied into grids before concrete pouring, ensuring structural integrity under stress, loads, or environmental forces.

View Video

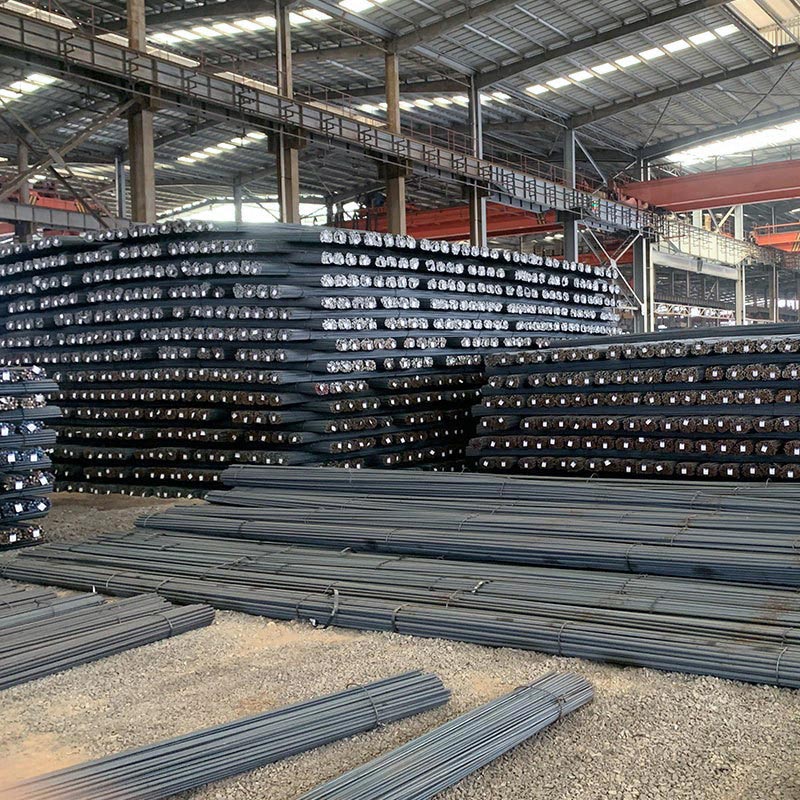

A615 Steel Rebar

A615 Steel Rebar is a widely used reinforcing bar conforming to ASTM A615 standards, designed for concrete reinforcement. Available in grades like 40, 60, and 75 (indicating minimum yield strengths in ksi), it features a deformed surface to ensure strong bonding with concrete. Offering good ductility and weldability, it suits various construction applications—buildings, bridges, highways, and precast structures. Manufactured via hot rolling, it meets strict quality criteria for strength and consistency. Its reliability and standardization make it a staple in North American and global projects, providing cost-effective, durable reinforcement for structural stability.

Get A Quick Quote!

You Can Leave Us A Message

or Send Us An Email!

Product Details

Product Parameters

Packaging and Transportation

Related Products

Leave Us Message

Please give us a message

What are you lookking for?