Wear Steel Plate

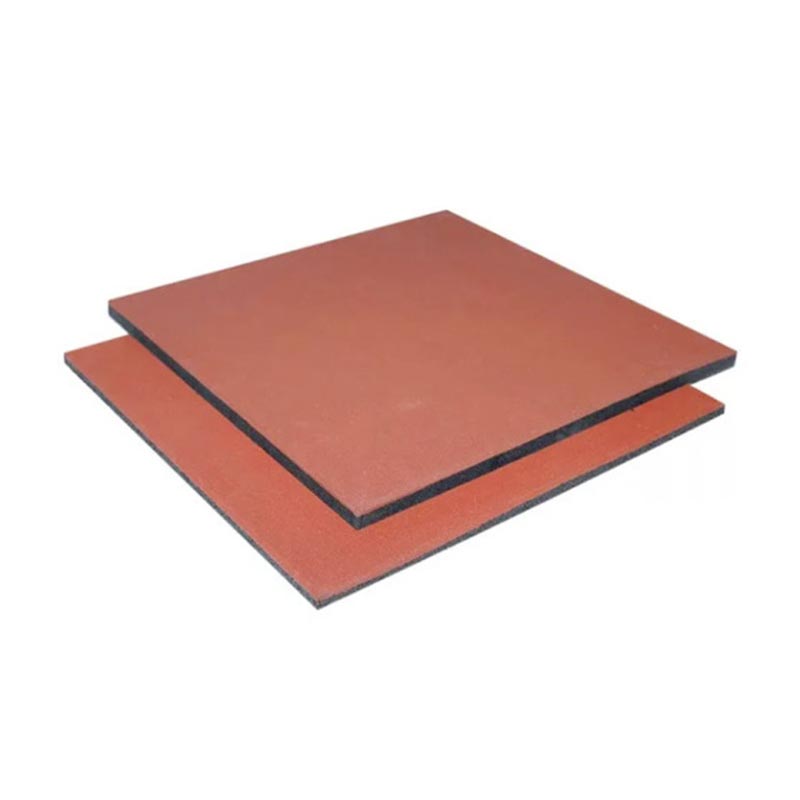

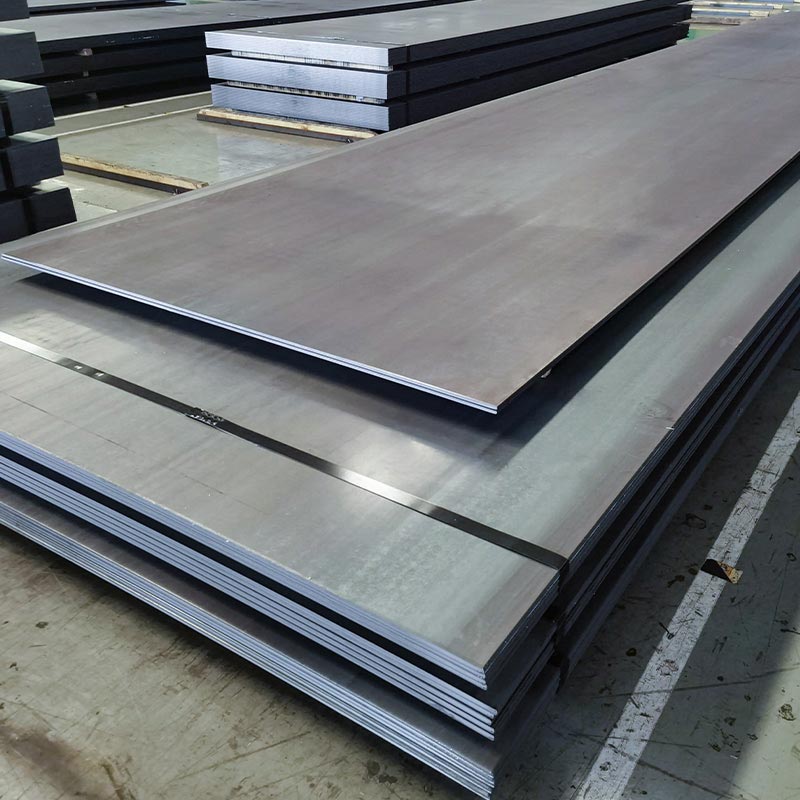

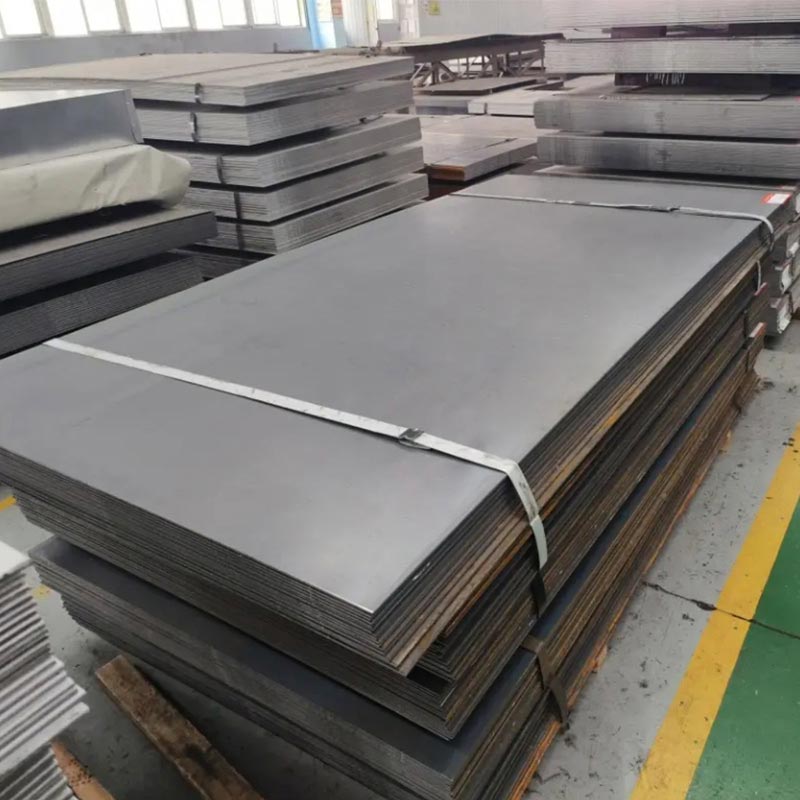

● A wear plate is a thick, durable metal sheet designed to resist abrasion, impact, and wear. Typically made from high-carbon steel or alloy steel (e.g., NM400, NM500 grades), it combines hardness with toughness.

● Its surface is engineered for maximum wear resistance, while the base layer ensures structural strength. Used to protect machinery, equipment, or surfaces exposed to friction, impact, or erosion—such as mining tools, industrial conveyors, or construction machinery.

● Available in various thicknesses, wear plates extend the lifespan of components by absorbing damage, reducing maintenance needs in high-wear environments.

View Video

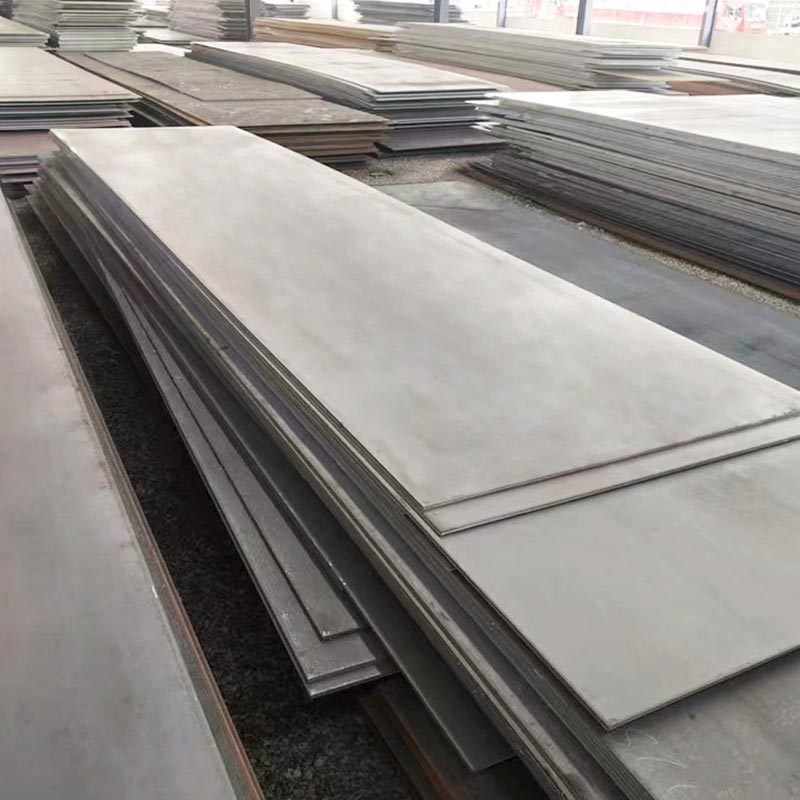

NM550 Steel Plate (NM550 Plate)

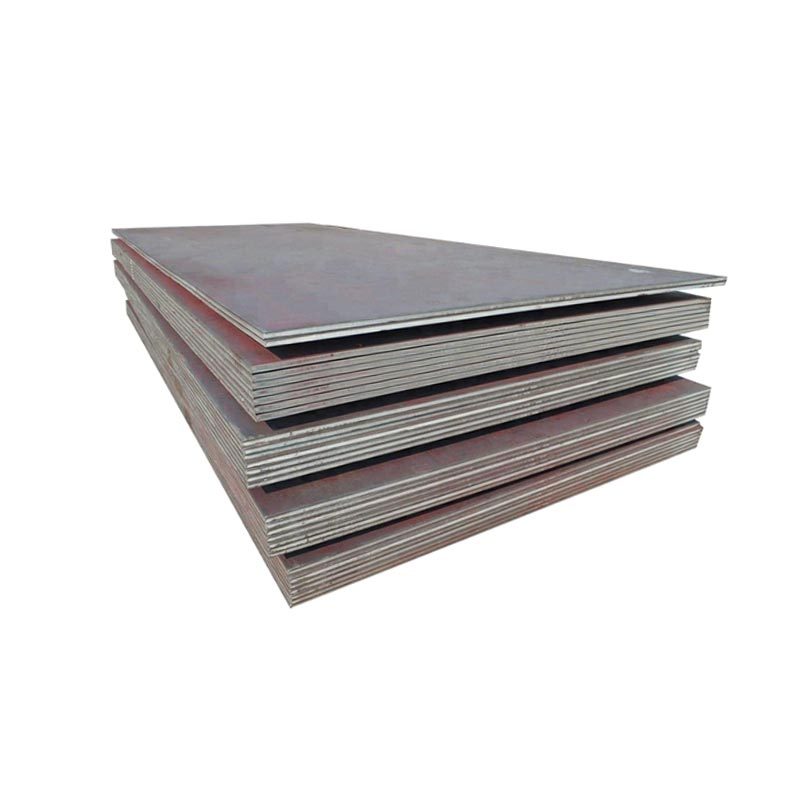

NM550 Steel Plate is an ultra-high-performance abrasion-resistant steel plate, designed for the most extreme wear conditions. With a minimum Brinell hardness of 550 HB, it delivers exceptional resistance to severe scraping, impact, and erosion, outperforming lower NM grades. Crafted from high-alloy steel, it balances extreme hardness with necessary toughness, allowing limited fabrication through specialized cutting and welding. Widely used in heavy mining machinery, dredging equipment, and high-wear industrial components, it significantly extends equipment life, minimizes maintenance, and ensures reliability under intense abrasive stress, making it ideal for critical, high-wear applications.

Get A Quick Quote!

You Can Leave Us A Message

or Send Us An Email!

Product Details

Product Parameters

Packaging and Transportation

Related Products

Leave Us Message

Please give us a message

What are you lookking for?