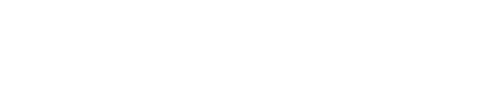

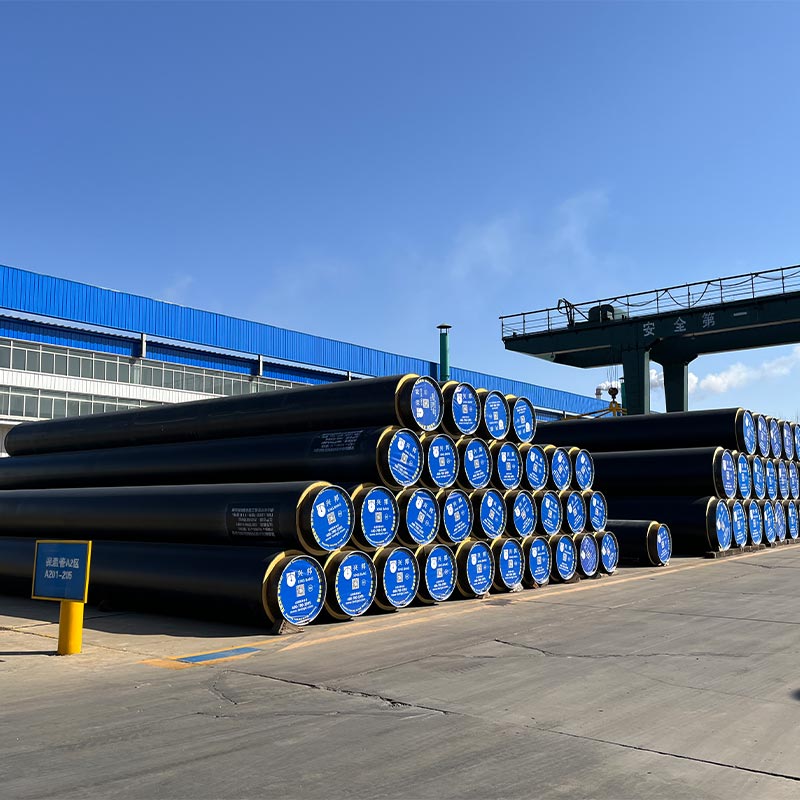

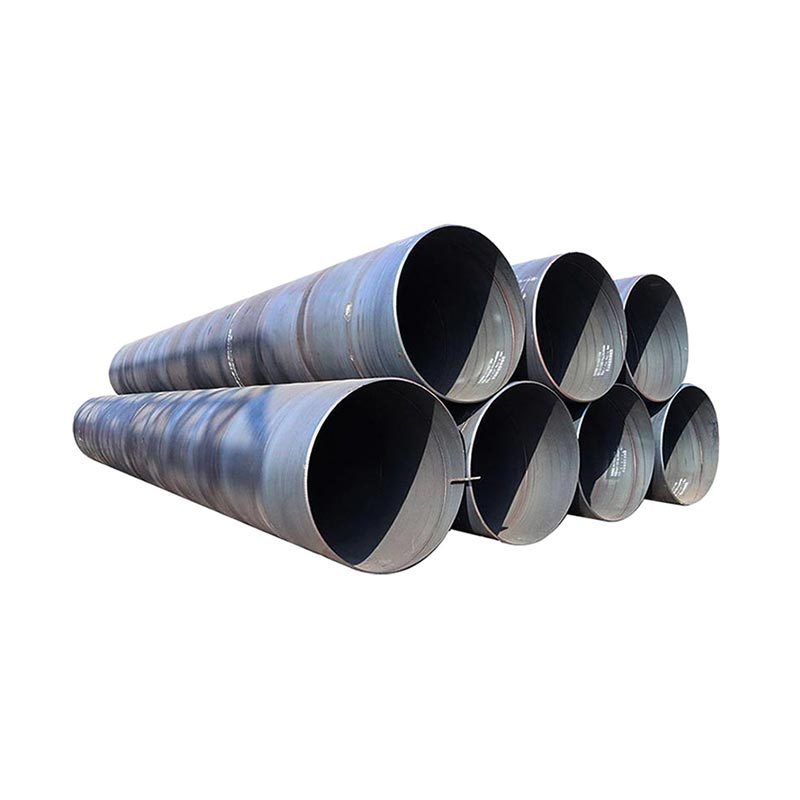

Carbon Steel Pipe

● A carbon steel pipe is a cylindrical tube made from carbon steel, an alloy of iron and carbon with trace elements. Classified by carbon content (low, medium, high), it balances strength, durability, and cost-effectiveness.

● Low-carbon pipes (e.g., A53) excel in weldability and ductility, used for water, gas, or structural applications. Medium-carbon types offer higher strength, suited for industrial pipelines. High-carbon variants, though harder, are less common due to reduced flexibility.

● Widely used in construction, oil/gas, and manufacturing, these pipes come in various sizes and wall thicknesses, with seamless or welded designs, serving fluid transport and structural roles.

View Video

ASTM A213 Carbon Steel Tube

ASTM A213 covers seamless ferritic and austenitic alloy steel tubes, designed for high-temperature service in boilers, heat exchangers, and superheaters. Available in various grades (e.g., T11, T22, 304), they offer excellent creep resistance and oxidation resistance at elevated temperatures. With precise dimensions and uniform mechanical properties, these tubes efficiently handle high-pressure, high-heat conditions in power generation, petrochemical, and industrial processes, ensuring reliable performance in critical thermal systems.

Get A Quick Quote!

You Can Leave Us A Message

or Send Us An Email!

Product Details

Product Parameters

Packaging and Transportation

Related Products

Leave Us Message

Please give us a message

What are you lookking for?