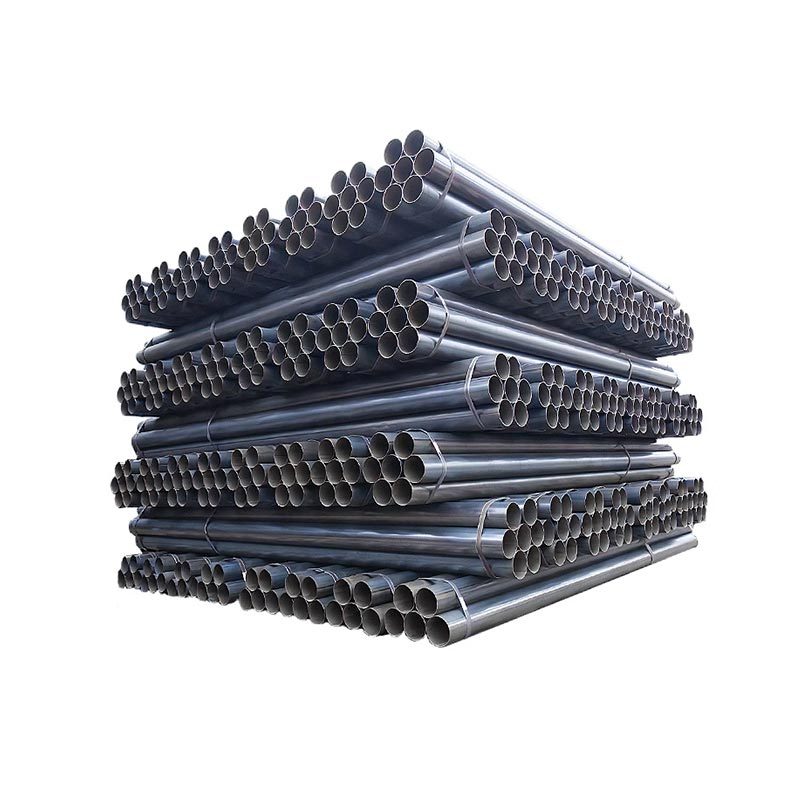

Carbon Steel Pipe

● A carbon steel pipe is a cylindrical tube made from carbon steel, an alloy of iron and carbon with trace elements. Classified by carbon content (low, medium, high), it balances strength, durability, and cost-effectiveness.

● Low-carbon pipes (e.g., A53) excel in weldability and ductility, used for water, gas, or structural applications. Medium-carbon types offer higher strength, suited for industrial pipelines. High-carbon variants, though harder, are less common due to reduced flexibility.

● Widely used in construction, oil/gas, and manufacturing, these pipes come in various sizes and wall thicknesses, with seamless or welded designs, serving fluid transport and structural roles.

View Video

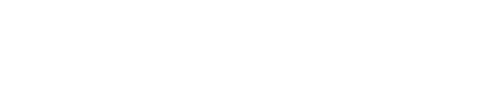

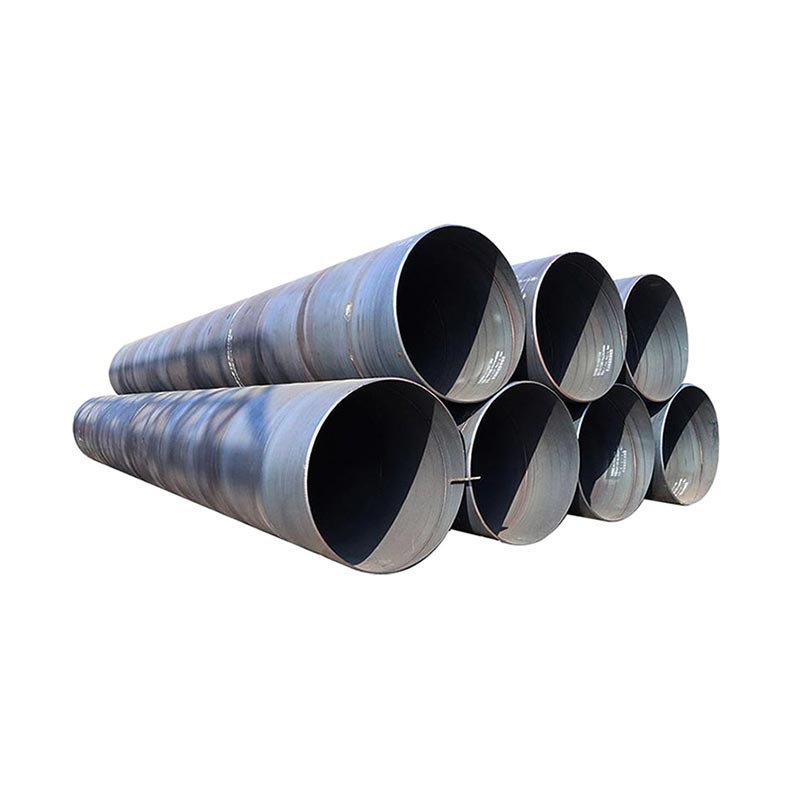

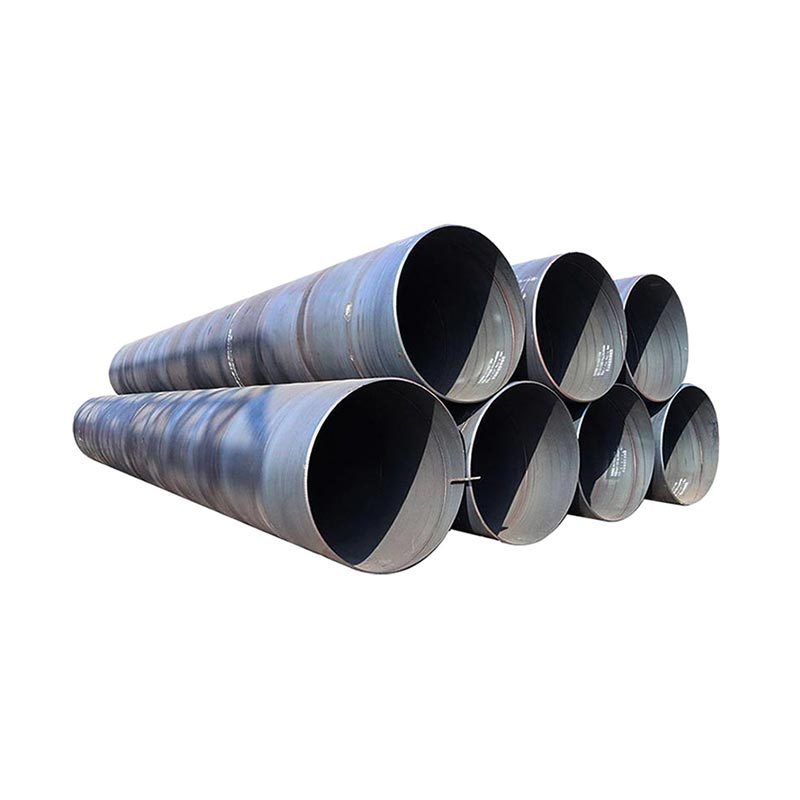

Carbon Steel Spiral Tube

Carbon steel spiral tube is made by helically winding a steel strip and welding the seams, forming a continuous, strong structure. It offers large diameters with consistent wall thickness, suitable for high-volume fluid transport like water, gas, or oil. With good weldability and cost-effectiveness, it’s widely used in pipelines, drainage systems, and industrial ducting. Its spiral design enhances structural stability, making it ideal for long-distance infrastructure and heavy-duty applications requiring reliable, large-capacity conveyance.

Get A Quick Quote!

You Can Leave Us A Message

or Send Us An Email!

Product Details

Product Parameters

Packaging and Transportation

Related Products

Leave Us Message

Please give us a message

What are you lookking for?