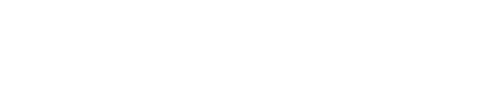

Carbon Steel Plate

● A carbon steel plate is a flat sheet made from carbon steel, an alloy primarily composed of iron and carbon, with minimal other elements. It’s categorized by carbon content: low (≤0.25%), medium (0.25–0.6%), and high (>0.6%).

● Low-carbon plates offer ductility and weldability, ideal for construction or automotive parts. Medium-carbon variants balance strength and toughness, used in machinery. High-carbon types are hard but brittle, suited for tools or springs.

● Common grades include A36, S235JR, and A572. These plates vary in thickness, width, and finish, serving industries like construction, manufacturing, and energy for structural, industrial, or fabrication needs.

View Video

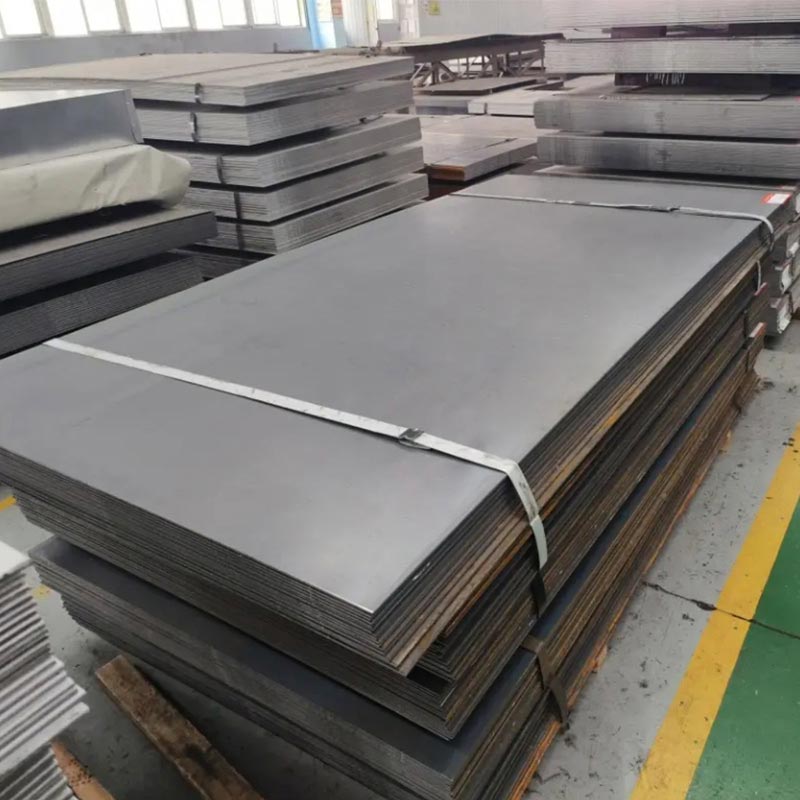

A36 Carbon Steel Plate

A36 Carbon Steel Plate is a structural steel plate meeting ASTM A36/A36M standards. With ≤0.25% carbon, it offers 250 MPa min yield strength and 400 MPa min tensile strength, plus good ductility (20-23% elongation).

It features excellent weldability, machinability, and formability. Widely used in construction (beams, frames), machinery, shipbuilding, and storage tanks. Equivalent to materials like GB Q235B, it balances strength and workability for diverse structural needs.

It features excellent weldability, machinability, and formability. Widely used in construction (beams, frames), machinery, shipbuilding, and storage tanks. Equivalent to materials like GB Q235B, it balances strength and workability for diverse structural needs.

Get A Quick Quote!

You Can Leave Us A Message

or Send Us An Email!

Product Details

Product Parameters

Packaging and Transportation

Related Products

Leave Us Message

Please give us a message

What are you lookking for?